- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Rubber Dust Ring Manufacturer, Supplier, Factory

Our intention would be to provide top quality products and solutions at competitive charges, and top-notch support to customers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Rubber Dust Ring,Dust Seal Ring,Dust Wiper Seal,Rubber Dust Wiper Ring,Wiper Scraper Seal, Our organization has been devoting that "customer first" and committed to helping clients expand their small business, so that they become the Big Boss !

Rubber Dust Ring, With the support of our highly experienced professionals, we manufacture and supply best quality goods. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the have to have of customers to meet the requirement of customers.

Hot Products

Guide Ring of MPMDS Series

Guide Ring of MPMDS Series mainly serves as a guide and is mainly used for guiding pistons and piston rings in hydraulic cylinders and pneumatic cylinders, playing a supporting and guiding role.Customized Welded Cylinder Base

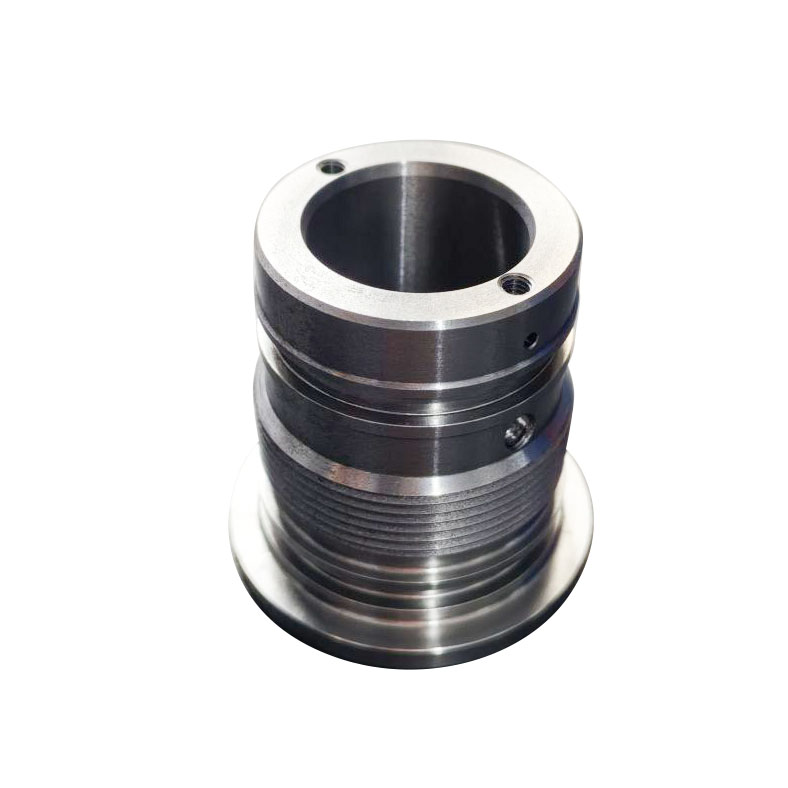

Customized Welded cylinder Base, also known as welded cylinder base end, is specially processed as customer's drawing and special requirement. The main function is to form an enclosed space with the cylinder to accommodate the hydraulic oil and piston assembly, while ensuring the tightness of the hydraulic cylinder, preventing oil leakage, and providing support for the piston rod and the whole hydraulic cylinder to ensure its stable work, which is similar function as common welded cylinder base.Injection Molding Machine Injection Hydraulic Cylinder

Injection molding machine injection hydraulic cylinder produced by Qingdao Micro Precision Machinery Co., Ltd. in China is used to inject molten plastic material into the grinding tool to form the required product. The working principle is to use the hydraulic system to hydraulically pump high-pressure oil into the cylinder to push the piston. Move forward and inject the injection molding material into the mold.Hydraulic Cylinder for Crane Support Legs

Hydraulic Cylinder for Crane Support Legs is an important part of the crane outrigger system. It adopts the hydraulic transmission principle and drives the outriggers to extend and retract through liquid pressure to achieve stable support of the crane. The hydraulic cylinder is mainly composed of cylinder barrel, piston, seal and guide sleeve. The hydraulic oil enters the cylinder barrel through the pipeline, pushing the piston to reciprocate in the cylinder barrel, thereby realizing the extension and retraction of the outrigger.Excavator Bucket Cylinder

The excavator bucket cylinder produced by Qingdao Micro Precision Machinery Co., Ltd. serves customers such as CAT, Volvo, SANY, etc. Qingdao Micro Precision Machinery Co., Ltd. can provide you with professional services and more favorable prices for hydraulic cylinder products. If you are interested in hydraulic cylinder products, please contact us. We adhere to reliable quality, conscientious pricing, and enthusiastic service. We can provide you with: • Bucket Cylinder • Boom Cylinder • Bucket Rod Cylinder • Bulldozer Hydraulic Cylinder • Steering Hydraulic Cylinder • Angle Push Oil Cylinder • Chassis Telescopic Oil Cylinder Customizable according to customer requirementsExcavator Swing Hydraulic Cylinder

Excavator Swing Hydraulic Cylinder pushes the piston to move through the pressure of the hydraulic oil, thereby driving the upper body of the excavator to rotate left and right relative to the lower chassis. It is generally installed in the slewing mechanism of the excavator and works in conjunction with other components to enable the excavator to flexibly change the working direction and angle in various construction scenarios.