- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

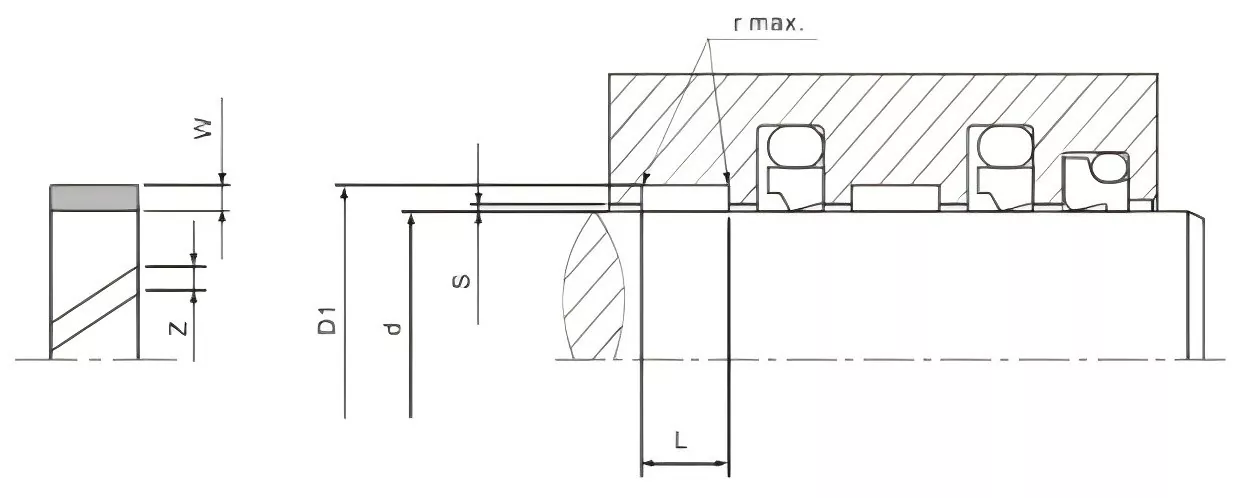

Guide Ring of MPMDS Series

Guide Ring of MPMDS Series mainly serves as a guide and is mainly used for guiding pistons and piston rings in hydraulic cylinders and pneumatic cylinders, playing a supporting and guiding role.

Send Inquiry

Guide ring, also called a support ring, is a part used on the piston or piston rod of a hydraulic cylinder or a gas cylinder to support the movement of the piston or piston rod. It can prevent the piston or piston rod from direct contact and friction with the cylinder body during movement, and protect the cylinder body and the piston or piston rod from damage. The commonly used material for guide rings is polyoxymethylene (POM).

Groove surface characteristics

|

Finish |

Rtmax (um) |

Ra (um) |

|

SlidingSurface |

≤2.5 |

0.05 - 0.3 |

|

GrooveBottom |

≤10 |

≤1.6 |

|

GrooveSide |

≤15 |

≤3 |

Specification

|

Rod Diameter |

Bottom Diameter |

Groove Width |

GuideRingThickness |

Guide Ring Clearance |

|

d f8/h9 |

D1 H8 |

L+0.2 |

W |

Z |

|

8-20.0 |

d +3.10 |

2.5 |

1.55 |

1-2 |

|

10-50.0 |

d +3.10 |

4 |

1.55 |

1-3 |

|

15-140.0 |

d +5.00 |

5.6 |

2.5 |

2-5 |

|

20-220.0 |

d +5.00 |

9.7 |

2.5 |

2-9 |

|

80-400.0 |

d +5.00 |

15 |

2.5 |

4-15 |

|

200-999.9 |

d +5.00 |

25 |

2.5 |

8-33 |

|

1000-4200.0 |

d +5.00 |

25 |

2.5 |

33-134 |

|

280-999.9 |

d +8.00 |

25 |

4 |

10-33 |

|

1000-2200.0 |

d +8.00 |

25 |

4 |

33-70 |

Limit clearance S

|

Cylinder Diameter |

Smin. |

Smax. |

D |

Rmax. |

|

8-20 |

0.20 |

0.30 |

8-250 |

0.2 |

|

20-100 |

0.25 |

0.40 |

>250 |

0.4 |

|

101-250 |

0.30 |

0.60 |

||

|

251-500 |

0.40 |

0.80 |

||

|

501-1000 |

0.50 |

1.10 |

||

|

>1001 |

0.60 |

1.20 |

||

GET A QUOTATION NOW

Filled with PTFE

Features

Non-metallic guide belt for piston rod, available in ready-to-use and on-site cutting types

▶Material

-Wear-resistant ring is PTFE bronze composite

▶Performance

Non-metallic guide element for piston rod, also suitable for ISO10766 standard cavity.

-Metal/plastic material pairing prevents "blocking" and "seizure" Limited load capacity (material);

-Low friction, no stick-slip phenomenon; suitable for dry running working conditions with poor lubrication;

-Good vibration damping (radial vibration);

-Can run-in possible foreign impurities;

-Guide ring corner rounding prevents edge gap extrusion "extrusion" at the semi-circular corner of the cavity groove.

>Working conditions

Linear speed: ≤15 m/s;

Load capacity: ≤15 N/mm2, at 20℃; <7.5N/, at 80℃; <5N/mm2, at 120C. Maximum operating temperature: -60°C~+150°C (200°C).

Phenolic Cloth

▶Features

Non-metallic guide element for piston.

▶Material

-Wear-resistant ring is phenolic cloth

▶Performance

Used as non-metallic guide element for piston rod, also suitable for IS010766 standard cavity.

-Metal/plastic material pairing prevents "blocking" and "seizure" phenomena;

-High load bearing capacity, elastic before reaching brittle working temperature;

-Guide ring corner rounding prevents edge extrusion "extrusion" at the semi-circular corner of the cavity groove.

▶Working conditions

Line speed: <1m/s

Load capacity: <50N/mm2, below 120C Maximum working temperature: -60℃~+120°C