- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

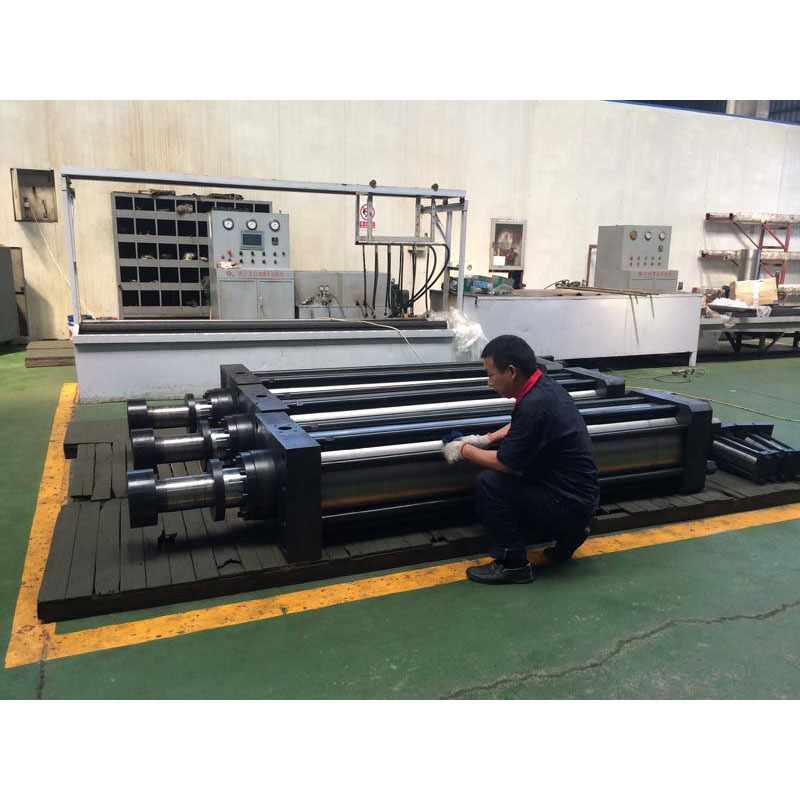

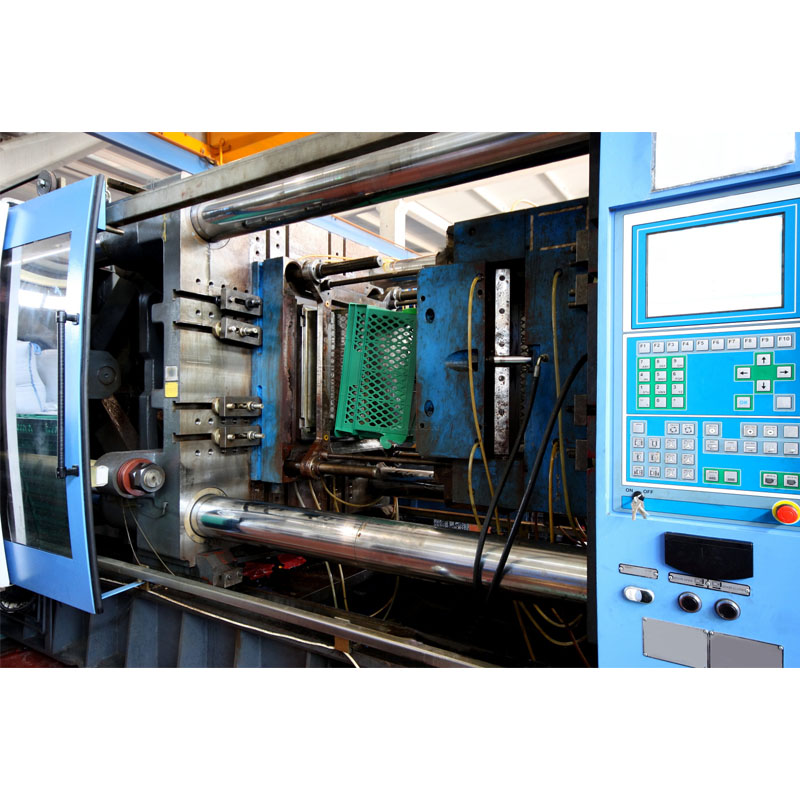

Injection Molding Machine Injection Hydraulic Cylinder

Injection molding machine injection hydraulic cylinder produced by Qingdao Micro Precision Machinery Co., Ltd. in China is used to inject molten plastic material into the grinding tool to form the required product. The working principle is to use the hydraulic system to hydraulically pump high-pressure oil into the cylinder to push the piston. Move forward and inject the injection molding material into the mold.

Send Inquiry

The function of the injection molding machine injection hydraulic cylinder: drives the injection platform to move.

Specifications:

Bore diameter 63mm~230mm

Rod diameter 36mm~190mm

Stroke≤1500mm

Thrust: Maximum 384KN

(Bore diameter 230mm/pressure 35MPa)

Accept customer customized models.

Material:

cast steel ZG270-500, cast steel ZG310-5, alloy steel 18MnMoNb, 45# steel ingot forging, 42CrMn overall forging.

Oil seal brands:

Japan NOK, Parker oil seal, American MPI, Swedish SKF, Austrian polyurethane oil seal.

GET A QUOTATION NOW

Advantages:

1. Injection cylinder of the injection molding machine has extremely high stability and improves production efficiency for customers.

2. All injection cylinder parts are produced by factory CNC machine tools with high precision.

3. Cylinders are assembled in dust-free workshops.

4. Cylinders enable precise control of injection volume.

5. Multiple tests are carried out before leaving the factory to ensure long-term stability and reliability.