- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Side Lock Tool Holder

The side lock tool holder is a common type of cutting tool holder, widely used in various CNC machines. It is locked by side fixing screws, easy to disassemble and assemble, with high precision and clamping force. It's suitable for heavy cutting processes. It's also called end mill holders or adapters. Tool holder can be customized to different sizes as customer's requirement.

Send Inquiry

The side lock tool holder secures the cutting tool by tightening the side screws, achieving tool clamping, it's also called end mill holders or adapters. It is mainly used for rough machining of tools with flattened shanks, such as drills and milling cutters. This tool holder is suitable for applications requiring high-speed and high-precision milling processes.

Product parameters:

| Order No.DIN69871.A×d-L1 | L | D | D1 | L2 | L3 | Wt(Kg) |

| DIN69871.A30×6-50 | 97.8 | 25 | 31.75 | 18 | 0.58 | |

| DIN69871.A30×8-50 | 97.8 | 28 | 31.75 | 18 | 0.64 | |

| DIN69871.A30×10-50 | 97.8 | 35 | 31.75 | 20 | 0.72 | |

| DIN69871.30×12-50 | 97.8 | 42 | 31.75 | 22.5 | 0.8 | |

| DIN69871.30×16-63 | 110.8 | 48 | 31.75 | 24 | 0.96 | |

| DIN69871.A40×6-50 | 118.4 | 25 | 44.45 | 18 | 0.92 | |

| DIN69871.A40×8-50 | 118.4 | 28 | 44.45 | 18 | 0.96 | |

| DIN69871.A40×10-50 | 118.4 | 35 | 44.45 | 20 | 2 | |

| DIN69871.A40×12-50 | 118.4 | 42 | 44.45 | 22.5 | 1.12 | |

| DIN69871.A40×14-50 | 118.4 | 44 | 44.45 | 22.5 | 1.12 | |

| DIN69871.A40×16-63 | 131.4 | 48 | 44.45 | 24 | 1.2 | |

| DIN69871.A40×18-63 | 131.4 | 50 | 44.45 | 24 | 1.2 | |

| DIN69871.A40×20-63 | 131.4 | 52 | 44.45 | 25 | 1.32 | |

| DIN69871.A40×25-100 | 168.4 | 65 | 44.45 | 24 | 25 | 2.04 |

| DIN69871.A40×32-100 | 168.4 | 72 | 44.45 | 24 | 28 | 2.24 |

| DIN69871.A40×40-120 | 188.4 | 90 | 44.45 | 30 | 32 | 2.4 |

| DIN69871.50×6-63 | 164.75 | 25 | 69.85 | 18 | 3.3 | |

| DIN69871.50×8-63 | 164.75 | 28 | 69.85 | 18 | 3.4 | |

| DIN69871.A50×10-63 | 164.75 | 35 | 69.85 | 20 | 3.42 | |

| DIN69871.A50×12-63 | 164.75 | 42 | 69.85 | 22.5 | 3.42 | |

| DIN69871.A50×14-63 | 164.75 | 44 | 69.85 | 22.5 | 3.44 | |

| DIN69871.A50×16-63 | 164.75 | 48 | 69.85 | 24 | 3.46 | |

| DIN69871A50×18-63 | 164.75 | 50 | 69.85 | 24 | 3.48 | |

| DIN69871.50×20-63 | 164.75 | 52 | 69.85 | 25 | 4.24 | |

| DIN69871.A50×25-80 | 181.75 | 65 | 69.85 | 24 | 25 | 4.4 |

| DIN69871.A40×32-100 | 201.75 | 72 | 69.85 | 24 | 28 | 4.52 |

| DIN69871.A40×40-120 | 221.75 | 90 | 69.85 | 30 | 32 | 4.72 |

GET A QUOTATION NOW

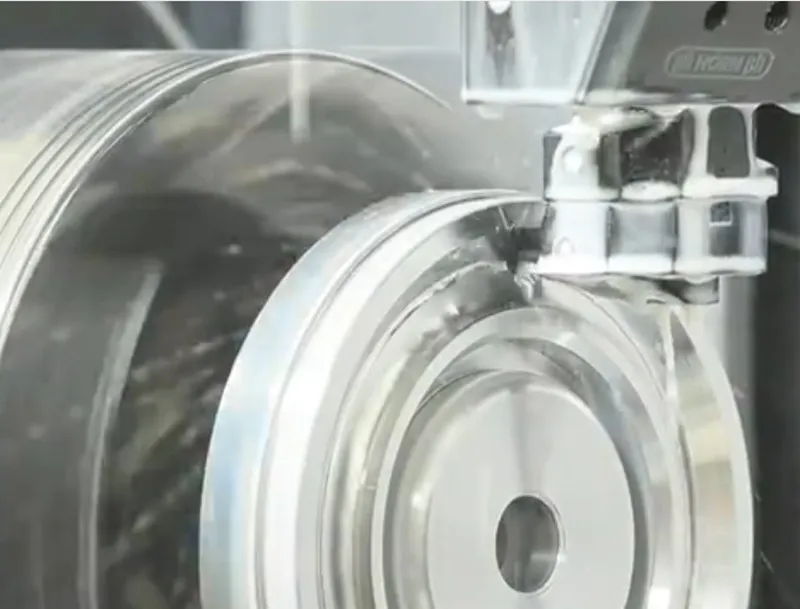

Production process for side lock tool holder:

The front taper shank and rear inner hole of the tool holder body are machined to ensure dimensional accuracy and surface roughness meet the requirements.The peripheral threaded holes of the tool holder body are machined, ensuring that the centerline of the threaded holes forms a certain angle with the radial direction of the inner hole, facilitating the installation of the locking screws.

Packaging: