- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

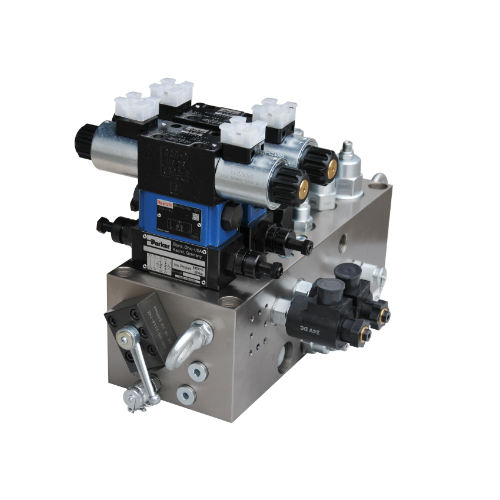

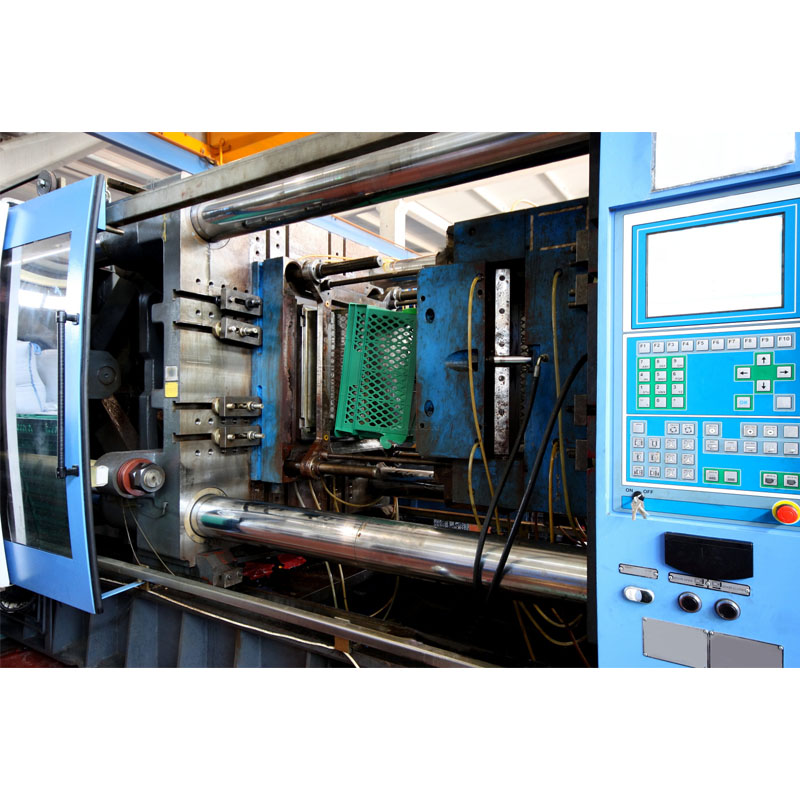

Sanitation Vehicle Locking Cylinder

The China Sanitation Vehicle Locking Cylinder produced by Micro Precision Machinery is a critical hydraulic component in sanitation vehicles, used to securely lock and release compartments or compacting mechanisms. With a compact design and high load capacity, it ensures stable operation under heavy-duty conditions, enhancing safety and efficiency.

Send Inquiry

The Sanitation Vehicle Locking Cylinder is a vital actuator in specialized sanitation vehicles (e.g., garbage compactors, street sweepers), primarily designed for secure locking and rapid release of operational mechanisms. Constructed with high-strength materials and precision sealing technology, it ensures long-term reliability under frequent starts/stops, vibrations, and heavy loads. Its key functions include preventing accidental compartment openings, stabilizing compacting mechanisms, and adapting to demanding working conditions.

With the trend toward intelligent sanitation equipment, modern locking cylinders increasingly incorporate sensors and electro-hydraulic controls for real-time monitoring and remote operation. Optimized designs reduce energy consumption and maintenance needs while enhancing vehicle automation and operational accuracy, making them a critical component for efficient and safe sanitation operations.

Material:

1. Cylinder Barrel Material: High-Quality Carbon Steel (45# Steel); Alloy Structural Steel (27SiMn); Stainless Steel (304/316)

2. Piston Rod Material: Chrome-Plated Alloy Steel (42CrMo); Stainless Steel Piston Rod (17-4PH)

3. Seal Material: Nitrile Rubber (NBR); Fluorocarbon Rubber (FKM); Polyurethane (PU)

4. Other Key Component Materials:

(1) Guide Sleeve: Wear-resistant bronze (ZCuSn10Pb1) or modified polyoxymethylene (POM)

(2) End Cap: QT500-7 ductile iron or 45# steel

(3) Fasteners: Grade 8.8/12.9 high-strength bolts

5. Surface Treatment Processes:

Piston Rod: Hard chrome plating (HV≥800) + polishing (Ra≤0.2μm)

Cylinder Bore Interior: Honing (Ra≤0.4μm)

Anti-Corrosion Coating: Dacromet or zinc-nickel alloy plating

6. Seal Brand:NOK, Parker, MAPKER, SKF, etc.

7. Maintenance Guidelines:

- Seal Replacement: Every 2 years or 500K cycles (Condition-based)

- Oil Cleanliness: NAS 1638 Class 8 or higher

- Corrosion Inspection: Biannual checks for coastal areas

Parameter:

|

Model |

Bore Size/mm |

Bore Size/mm |

Work Pressure/MPa |

|

Sanitation Vehicle Locking Cylinder |

40-63 |

22-35 |

15-30 |

Service

25 years of experience in hydraulic cylinder manufacturers

MPM cylinders are mainly used in:

1- Construction machinery

(Hydraulic lifting cylinders and steering cylinders for cranes/forklifts/tractors/loaders/excavators)

2- Industrial equipment

(Hydraulic cylinders/tie rod cylinders/compact cylinders)

3- Ships and offshore machinery

(Heavy cylinders, stainless steel hydraulic cylinders)

If you can provide us with the following technical parameters, we can design and customize piston hydraulic cylinders according to your needs:

1. Bore

2. Rod diameter

3. Stroke

4. Working pressure

5. Installation type6. Push or pull back capacity