- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

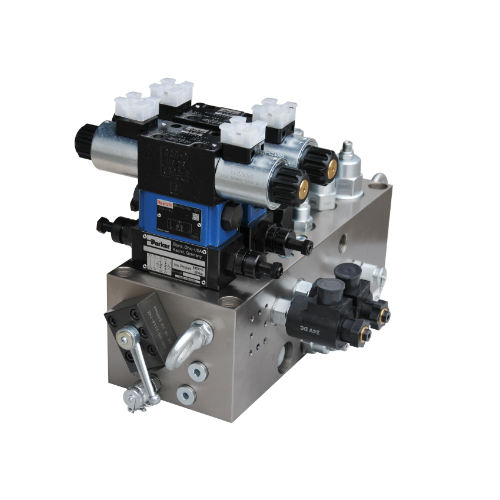

T3A Hydraulic Cylinder Balance Valve Block

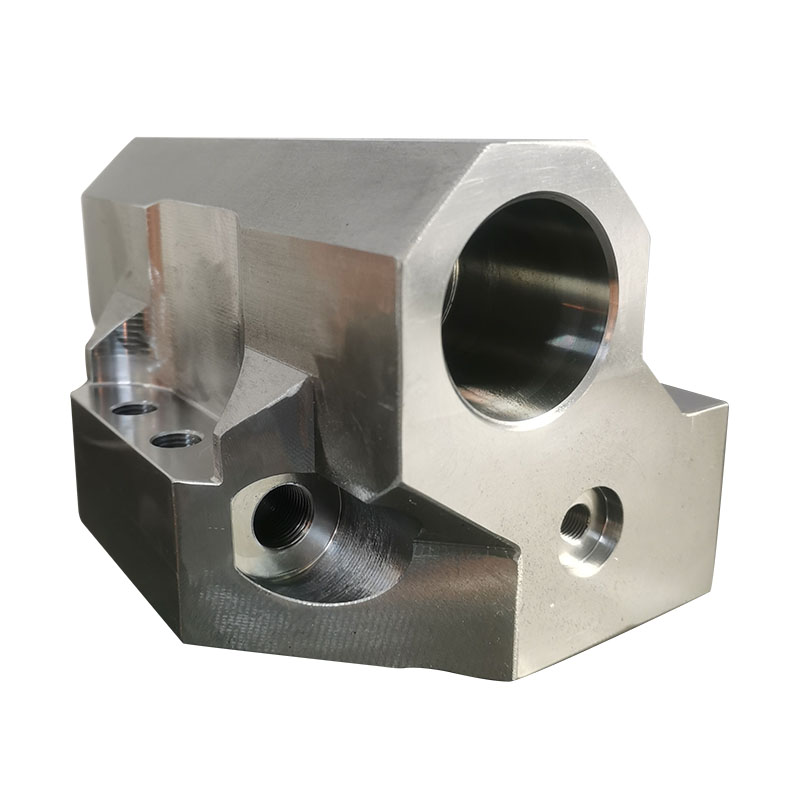

The material of the T3A hydraulic cylinder balance valve block; Q355D forged, 20# steel, GGG50, etc. Each piece is subjected to flaw detection testing to prevent oil leakage and oil channeling in the hydraulic valve block.

Send Inquiry

T3A Hydraulic Cylinder Balance Valve Block

Advantages of T3A Hydraulic Cylinder Balance Valve Block:

Precisely control the flow of hydraulic systems,

Precisely control the pressure of the hydraulic system,

Realize automatic control of hydraulic system,

Improve the reliability and safety of hydraulic systems

The material of the T3A Hydraulic Cylinder Balance Valve Block; Q355D forged, 20# steel, GGG50, etc. Each piece is subjected to flaw detection testing to prevent oil leakage and oil channeling in the hydraulic valve block.

The T3A hydraulic cylinder balance valve block has extremely high cost performance and high quality inspection requirements.

Professional cleaning equipment and professional deburring equipment for the T3A hydraulic cylinder balance valve block ensure the cleaning of the hydraulic valve block and the deburring of the cross holes. Ensure that each valve block achieves 3D imaging detection. It effectively prevents the existence of iron filings and avoids the unsmooth movement of the hydraulic valve block.

The hydraulic cylinder balance valve block can be processed with materials specified by customers and can be processed with non-standard customization to ensure quality and timely delivery.

The valve hole of the hydraulic cylinder balance valve block adopts cone surface sealing to ensure small leakage. It is also suitable for low-viscosity working media such as emulsion. It has a simple structure, reliable operation, and a high degree of standardization.

For more complex hydraulic systems with large flow rates and high pressures, the size and weight can be significantly reduced.

GET A QUOTATION NOW

Working principle of T3A hydraulic cylinder balance valve block:

1: The pressure reducing valve block uses the principle of pressure reduction when the oil passes through the gap, so that the outlet oil pressure remains stable and low.

2: The pilot-operated pressure reducing valve is composed of a pilot valve and a main valve. The pressure flows out from the oil inlet of the main valve and then out of the oil outlet.

3: When the oil outlet pressure is lower than the setting pressure of the pilot valve spring, the pilot valve is closed, the pressure in the upper and lower oil chambers of the main valve spool is equal, and it is at the lowest position under the force of the outlet valve spring, and the X opening is the largest. Acts as a stress reliever.

4: When the outlet pressure is higher than the setting pressure of the pilot valve spring, the pilot valve opens and the main valve spool rises. The X opening is the smallest, and the outlet pressure drops, which acts as a pressure reducer.

The T3A hydraulic cylinder balance valve block can set the pressure guide ratio 1.5:1 3:1 4.5:1