- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Oil Seal RS Series

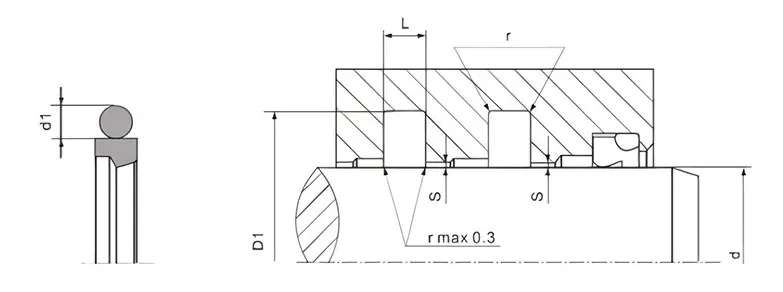

Oil seal RS series, also known as the piston rod one-way sealing ring, is composed of an anti-wear filled polytetrafluoroethylene PTFE ring and an O-type rubber sealing ring. The O-type ring provides elasticity to compensate for the wear of the PTFE step ring and only has a one-way sealing effect.

Send Inquiry

Single acting seals for piston rods in hydraulic cylinders are crucial components. These seals are designed to prevent fluid leakage in one direction. They work by creating a tight barrier between the piston rod and the cylinder housing.

Proper installation and maintenance of these seals are essential. Regular inspection for wear and damage helps ensure the hydraulic cylinder operates smoothly and without fluid loss. When functioning correctly, single acting piston rod seals contribute to the overall performance and reliability of the hydraulic equipment.

Product parameters:

Groove surface characteristics:

|

Finish |

Rtmax (um) |

Ra (um) |

|

SlidingSurface |

≤2.5 |

0.05 - 0.3 |

|

GrooveBottom |

≤6.3 |

≤1.6 |

|

GrooveSide |

≤15 |

≤3 |

|

|

|||||||

|

ShaftDiameter |

BottomDiameter |

Width |

Rounded Corner |

Smax* |

O-Ring |

||

|

Df8/h9 |

D1 H9 |

L+0.2 |

r |

10MPa |

20MPa |

40Mpa |

d1 |

|

3-7.9 |

D+4.9 |

2.2 |

0.4 |

0.30 |

0.20 |

0.15 |

1.78 |

|

8-18.9 |

D+7.3 |

3.2 |

0.6 |

0.40 |

0.25 |

0.15 |

2.62 |

|

19-37.9 |

D+10.7 |

4.2 |

1.0 |

0.40 |

0.25 |

0.20 |

3.53 |

|

38-199.9 |

D+15.1 |

6.3 |

1.3 |

0.50 |

0.30 |

0.20 |

5.33 |

|

200-255.9 |

D+20.5 |

8.1 |

1.8 |

0.60 |

0.35 |

0.25 |

7.00 |

|

256-649.9 |

D+24.0 |

8.1 |

1.8 |

0.60 |

0.35 |

0.25 |

7.00 |

|

650-999.9 |

D+27.3 |

9.5 |

2.5 |

0.70 |

0.50 |

0.30 |

8.40 |

|

>1000 |

D+38.0 |

13.8 |

3.0 |

1.00 |

0.70 |

0.60 |

12.00 |

GET A QUOTATION NOW

Materials

- Wear-resistant ring is PTFE bronze composite material;

- O-ring is nitrile rubber NBR or gas rubber FKM.

> Medium

General petroleum-based hydraulic oil, water glycol hydraulic oil, oil-water emulsion hydraulic oil.

Working conditions (the following limit values cannot appear at the same time)

Working pressure: ≤50MPa

Operating speed: ≤15 m/s

Working temperature: -35℃~+200℃ (depending on the material of the O-ring)