- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Is Synchronous Control Of Multiple Hydraulic Cylinders Achieved?

2024-12-24

Introduction

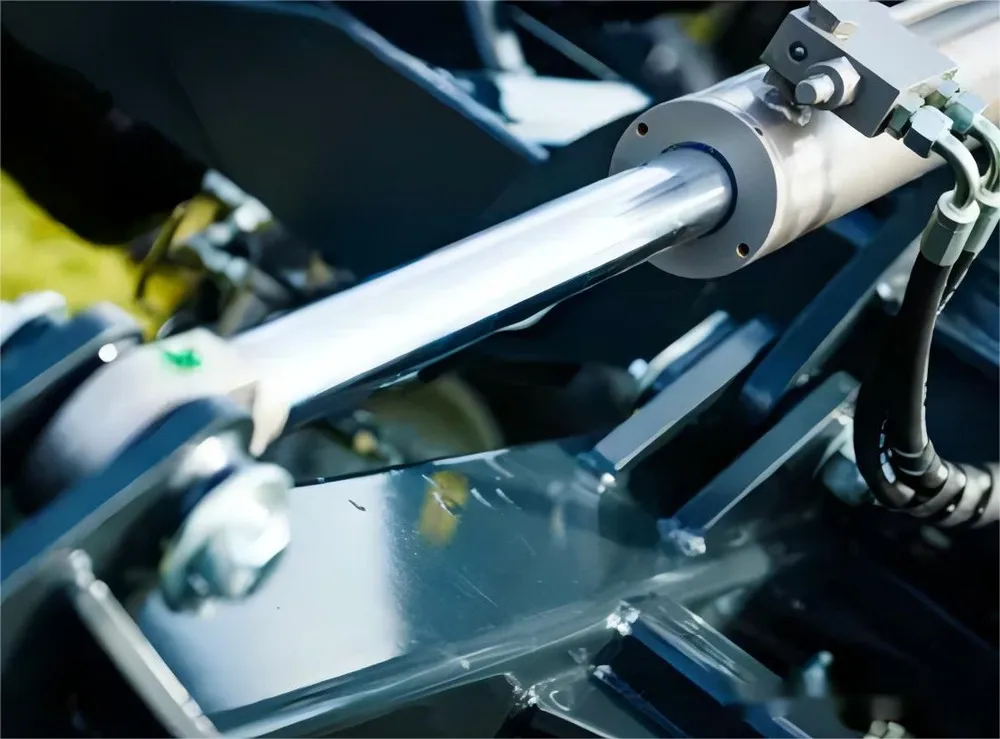

In modern industrial equipment, hydraulic systems are widely used for a variety of functions such as lifting, propulsion and driving. In these systems, the synchronous operation of multiple hydraulic cylinders is an important part of ensuring the efficient and safe operation of the equipment. The synchronization of hydraulic cylinders can not only improve work efficiency, but also avoid equipment damage caused by inconsistent movement. This article will explore the synchronization principles of multiple hydraulic cylinders, common synchronization methods, technical challenges, and precautions during operation.

How Does Hydraulic Cylinder Synchronization Work?

The synchronization of hydraulic cylinders means that multiple cylinders expand or contract at the same speed and force at the same time. The core lies in the uniform distribution of hydraulic fluid and the precise control of pressure. The realization of synchronous operation depends on the following key factors:

(1)Fluid Dynamics

The basic principle of the hydraulic system is to use the incompressibility of liquid to convert pressure into power. The synchronous movement of the cylinders is achieved by controlling the direction and flow of liquid flow.

(2)Load Balancing

When multiple hydraulic cylinders share the load, ensure that each cylinder is subjected to the same load to avoid asynchronism caused by uneven load.

(3)Real-Time Feedback

Through sensors and control systems, the movement status of each cylinder is monitored in real time, and adjustments are made as needed to maintain synchronization.

Common Methods For Synchronizing Hydraulic Cylinders?

(1)Mechanical Linkage

Mechanical linkage is a way to achieve synchronization through physical connection. In this system, multiple hydraulic cylinders are connected to each other through mechanical components, such as synchronization rods or gear systems. The physical connection ensures that the displacement of each cylinder is exactly the same when the cylinder moves. This method is usually used in applications where the synchronization accuracy is not high, and is suitable for simple and low-cost application scenarios.

(2)Flow Distributor

The flow distributor evenly distributes the hydraulic oil flow to each hydraulic cylinder. By adjusting the settings of the distributor, it can be ensured that each cylinder receives the same flow, thereby achieving synchronization. This method is usually used in hydraulic systems connected in parallel, such as applications where multiple hydraulic cylinders lift heavy objects together.

(3)Position Sensor

When high-precision synchronization is required, position sensors and feedback control systems can be selected. Each hydraulic cylinder is equipped with a position sensor to monitor its real-time displacement and transmit this data to the controller through a feedback control system. The controller fine-tunes the hydraulic valve based on the feedback data to ensure that the movement of each hydraulic cylinder is always synchronized. The advantage is that it can achieve extremely high synchronization accuracy through real-time feedback and can adapt to dynamic changes in the load. The disadvantage is that the system is highly complex, relies on electronic components, and has high technical requirements for installation, commissioning and maintenance.

(4)Hydraulic valve Control Diverter Valve

Diverter valves play a key role in hydraulic systems, ensuring that the flow supplied by a single oil source can be evenly or proportionally distributed to multiple actuators according to demand. Suitable for the synchronous control of multiple hydraulic cylinders, by accurately controlling the flow distribution, ensuring that each actuator (such as a hydraulic cylinder) maintains the same speed. Proportional valves: These precision valves allow precise regulation of the flow and pressure of hydraulic oil, and combine electronic signal inputs to achieve more accurate synchronization. They are usually combined with sensors and control systems to adjust the action of each hydraulic cylinder in real time.

Technical Challenges Of Hydraulic Cylinder Synchronization?

(1)Unbalanced Loads

When multiple hydraulic cylinders share a load, uneven distribution of loads may cause unsynchronized movement between cylinders. For example, in a lifting operation, if a cylinder is subjected to a large load, it may cause its speed to lag behind. Therefore, the use of flow control valves or counterbalance valves can effectively alleviate the problem of unbalanced loads.

(2)Temperature And Pressure Fluctuations

The temperature change of hydraulic oil affects its viscosity, which in turn affects the response speed of the cylinder. High temperatures may cause hydraulic oil to flow more, while low temperatures may increase the viscosity of hydraulic oil. In addition, pressure fluctuations may also cause unsynchronized movement of the cylinders, so temperature and pressure must be monitored and adjusted regularly.

(3)Wear And Aging

With the increase of use time, hydraulic cylinders and their components will wear, which may cause uneven movement and affect the synchronization effect. Therefore, regular maintenance and inspection are necessary to ensure that the system is in good condition.

(4)Complexity Of Control System

Although control systems provide a high degree of accuracy, their complexity and potential failures can pose challenges to operation. Operators need to have the corresponding skills to debug and maintain these systems.

In Summary

(1)Check In Advance

Before performing synchronous operation, be sure to check the condition of all hydraulic cylinders, including cylinders, seals and oil pipes to ensure that there is no wear or leakage.

(2)Set Reasonable Flow And Pressure

Ensure that the flow and pressure of the hydraulic system are set within a reasonable range to avoid inconsistent cylinder movement due to insufficient flow or overload.

(3)Monitor Temperature Changes

During operation, the temperature changes of the hydraulic oil should be monitored to prevent overheating or low temperature from affecting the performance of the system.

(4)Pay Attention To The Order Of Operation

During synchronous operation, ensure that the hydraulic cylinders are operated in the correct order to avoid asynchronous problems caused by improper operation.

(5)Timely Adjustment And Correction

During synchronous operation, if a cylinder is found to be lagging or ahead, the flow and pressure should be adjusted in time to restore the synchronous state.